LAKE MARY, Fla. (May 12, 2021) – Mitsubishi Power Americas, Inc., and Texas Brine Company, LLC have signed an agreement to develop large-scale long-duration hydrogen storage solutions to support decarbonization efforts across the eastern United States. Long-duration hydrogen storage is a Continue reading “Mitsubishi Power Americas & Texas Brine Company Agree To Develop Long Duration Hydrogen Storage”

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2021-Q1

Welcome new readers of RMP’s quarterly H2 infrastructure report. Each quarter we look back on the major stories related to hydrogen infrastructure advancements and we compare the current AFDC database to the AFDC database in the prior quarter to see what has changed. The AFDC database is updated by the US Dept of Energy & can be found by clicking here. Canada added a new data repository for hydrogen stations in Q2-2020. The Canadian website is administered by Natural Resources Canada. RMP will continue to use the US Department of Energy database as our primary data source as we learn more about the Canadian database. All this data (and more) goes into RMP’s interactive map of hydrogen infrastructure in the USA & Canada you can see by clicking here. Ok, on with the report…

The big story this quarter was supposed to be Navistar Inc. announcing they plan to bring a fuel cell Class 8 longhaul truck to market in 2024 with prototypes on California roads beginning next year. This news was made more interesting because the fuel cell stacks would be supplied locally by Detroit based General Motors. This news became slightly overshadowed, however, when CAFCP updated the planned hydrogen refueling station data for the next round of hydrogen stations from the latest 2020 CEC funding round. According to the data CAFCP uses to track station progress, almost all of the new planned stations will have a nameplate storage capacity of 1,600kg which is nearly 9x bigger than most of the Continue reading “USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2021-Q1”

GOPAL, SINGLETON BILL TO ENCOURAGE USE OF FUEL CELLS PASSES SENATE 37-0

Trenton, New Jersey – In an effort to utilize renewable energy across the state, today the Senate passed legislation sponsored by Senators Vin Gopal and Troy Singleton which would encourage the use of fuel cells as a power source.

“The State currently has the ambitious goal of securing 50 percent of its electricity supply from renewable energy by 2030, and utilizing fuel cells is a step in the right direction,” said Senator Gopal (D-Monmouth). “Fuel cells use the chemical energy of hydrogen or another fuel to cleanly and efficiently produce electricity that can be used to power a number of systems—from a utility power station to a laptop computer. This bill will help to increase the use of fuel cells within State government agencies and set an example for private companies to also do the same as we work to increase the use of renewable energy across the state.”

The bill, S-2846, would require State agencies that are seeking to purchase an item requiring a power source to include in the request proposals that allow for the consideration of items powered by fuel cells.

“Through this proposal, we are encouraging state agencies to consider fuel cells as an energy source when they are purchasing items,” said Senator Singleton (D-Burlington). “This will have the dual benefit of reducing our carbon footprint while at the same time serving as an example for those in the private industry to follow. Ultimately, it is our hope that this will pave the way for more renewable energy throughout New Jersey.”

The bill cleared committee by a vote of 37-0.

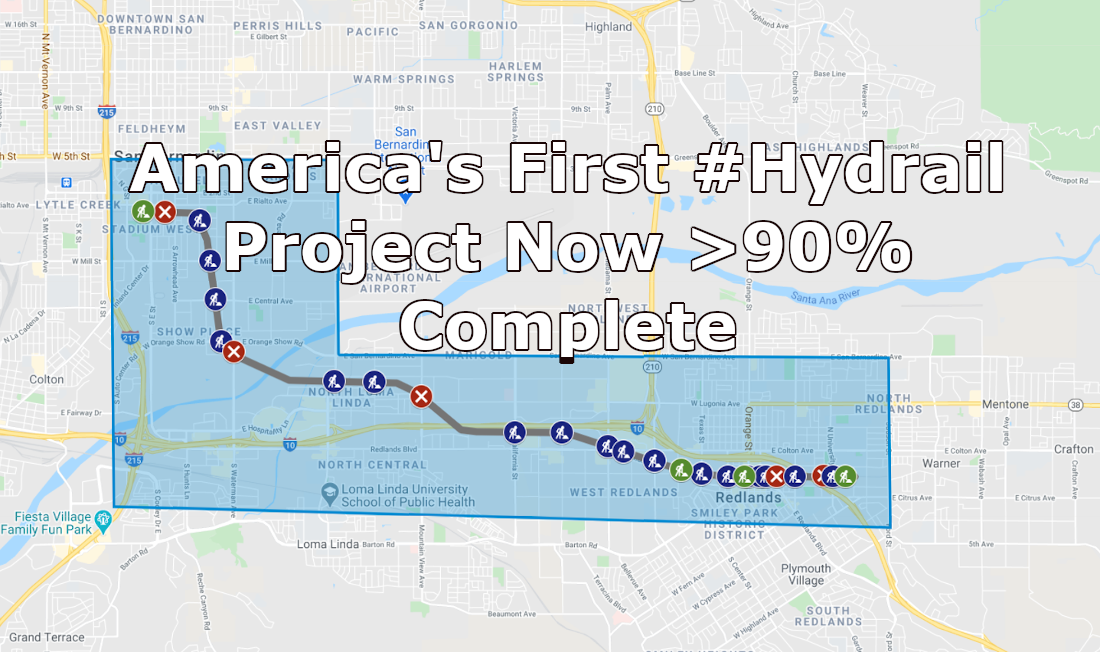

Redlands Passenger Rail Project Update – America’s 1st Hydrail >90% Complete

Construction on the 9-mile Arrow corridor almost 90% complete and bridge construction almost 100% complete. Crews continue working on setting the rail along the corridor; installing signals including cabling at the grade crossings; paving and reconstructing curbs, gutter, and sidewalks; installing perimeter fencing along the corridor where needed; completing the installation of underground utilities and drainage systems; and preparing for train testing.

RMP published a detailed post explaining every aspect of this hydrogen rail project on February 2, 2020 (just over 1 year ago). You can read that post by clicking here to learn more details about the project.

Sen. Brad Hawkins’ Bill on Hydrogen Fuel Cell Vehicles Unanimously Passes

Sen. Brad Hawkins’ bill to promote hydrogen-powered vehicles has cleared a major hurdle.

The Senate today voted 49-0 to approve Senate Bill 5000, which would establish an eight-year statewide pilot project for the reduction of sales tax on purchases of fuel-cell electric vehicles.

“I’m pleased to see such strong support from my Senate colleagues for this bill,” said Hawkins, who represents the 12th District. “Our state is still in its infancy regarding electric vehicles, so I think it’s helpful to promote different types of zero-emission vehicles, both battery electrics and fuel-cell electrics. Washington has the potential to be a key producer of renewable hydrogen, so it makes sense to make it easier to purchase hydrogen-fueled vehicles.”

Senate Bill 5000, which has bipartisan support and nearly 30 co-sponsors, now goes to the House of Representatives for further consideration.

Back in 2019, the Legislature approved Hawkins-sponsored Senate Bill 5588, which authorizes public utility districts to produce and sell “renewable hydrogen.”

“The people of North Central Washington have been leaders in clean energy for decades and now we’re in a position to lead the United States on renewable hydrogen use in transportation, including production, distribution, vehicles, transit buses, short haul agriculture, and long haul opportunities. It’s pretty exciting when you think about it, especially knowing my region’s long and proud history of clean energy,” said Hawkins.

Hydrogen can be created from a process that separates the hydrogen and oxygen molecules in water. The Douglas County Public Utility District in Hawkins’ district plans to utilize its surplus hydropower to do just that, creating renewable hydrogen from excess renewable hydropower and possibly also building hydrogen fueling stations. The PUD’s hydrogen production facility near East Wenatchee is expected to be completed toward the end of this year.

SB 5000 aims to extend a similar exemption on vehicle sales tax that purchasers of traditional electric vehicles receive. With the first hydrogen-fueling stations in Washington expected to be operational by 2022, the bill would allow a total of 650 vehicles to receive a 50-percent sales tax exemption in fiscal years 2023 through 2029.

Even though hydrogen vehicles are newer to the market and slightly more expensive due to having not been in mass production nationwide, they have shown tremendous promise given how quickly they refuel and the limited infrastructure required to get the fuel to the station.

Hawkins said his bill would help establish important parity between fuel-cell electric vehicles and traditional plug-in electrics.

“In our efforts to promote carbon-free vehicles, our state policies should be ‘technologically neutral’ so that we can give ourselves varied opportunities to reduce emissions and not unintentionally bias ourselves in the process,” Hawkins said. “Similar to diesel and gas, maybe there will always be multiple fuel sources for next-generation cars or maybe someday hydrogen vehicles will be the preferred choice.”

More Info: Renewable hydrogen could play a key role in Washington’s clean-energy future (Sen. Hawkins, Seattle Times, 12/15/20).

GTI Preparing to Launch First-of-a-Kind Pilot with Fuel Cell Yard Trucks

Performance verification is nearing completion on new zero-emissions fuel cell-electric terminal tractors, and a first-of a kind pilot project is preparing to launch. For 16 months, GTI and partners have been designing and assembling the tractors in a project called Zero Emissions for California Ports (ZECAP) that will assess vehicle operation in a demanding, real-world cargo-handling application. The hydrogen fueling equipment is in final assembly and slated for installation this spring, along with the delivery of trucks.

A terminal tractor, also called a yard truck, is a heavy-duty tractor designed to quickly couple and uncouple with trailers to move them within a cargo yard. More than 1,800 yard trucks operate at the Ports of Long Beach and Los Angeles, which is more than half of all cargo-handling equipment (CHE) at these ports. Yard trucks are the single largest source of CHE emissions but are more difficult to convert to zero-emission fuel cells or batteries because of their variable duty cycles and fundamental requirements for power, versatility, and durability.

In the ZECAP program, project partner TraPac will operate two fuel cell electric yard trucks for 12 months. The trucks are Capacity of Texas Trailer Jockey Series TJ9000 gliders configured with BAE Systems electric drive powertrain capable of peak propulsion power of 200kW (270 hp) and Ballard Power Systems FCveloCity®-HD85 85kW proton exchange membrane fuel cell. The Capacity truck can store 9.1kg of hydrogen at 350 bar and will fill at an onsite Hydrogen Technology & Energy Corporation (HTEC) hydrogen fueling station with 182kg storage capacity. Other project partners are Frontier Energy and ZEN Clean Energy Solutions. The California Air Resources Board (CARB) funded the project through a grant.

“We designed the project to maximize the time the trucks will be in service,” said Bart Sowa, GTI’s project manager. “TraPac is a 24-hour operation. The fuel cell yard trucks are expected to operate for two shifts and refill in minutes, with minimum disruption to TraPac’s operation. We’ll collect and analyze real-time operating data to evaluate safety, reliability, efficiency, and ability to meet operational requirements.”

This project is a step toward achieving the Ports of Long Beach and Los Angeles goal of using 100% zero emission cargo handling equipment by 2030.

The $11M project is part of California Climate Investments, a statewide initiative that puts billions of Cap-and-Trade dollars to work reducing greenhouse gas emissions, strengthening the economy, and improving public health and the environment – particularly in disadvantaged communities.

Hyzon Motors to Build Fuel Cell Material Production Facility in Chicago, Illinois

- Hyzon Motors chooses Chicago Area as Location for High-Volume Fuel Cell Membrane Electrode Assembly (MEA) Production Line

- Hyzon’s Fuel Cell Features Proprietary MEA Technology at its Core

- New Facility Expected to Substantially Reduce Costs for Fuel Cell Trucks Manufactured in the US, Eliminating a Key Bottleneck

- Facility’s Production of MEAs Expected to Boost Delivery Capacity of Hyzon Zero-Emission Trucks to as many as 12,000 Vehicles Annually, with Ability to Scale Further

March 1, 2021, Rochester, NY: Hyzon Motors Inc. (“Hyzon” or the “Company”), a leading supplier of zero-emission hydrogen fuel cell powered heavy vehicles, today announced plans to build the largest fuel cell membrane electrode assembly (MEA) production line for commercial vehicles in the United States at its new Hyzon Innovation Center located in Bolingbrook, Illinois, just outside of Chicago.

As announced previously, Hyzon plans to go public through a merger with Decarbonization Plus Acquisition Corporation (NASDAQ: DCRB, DCRBW, DCRBU), a publicly-traded special purpose acquisition company (SPAC). The combination is expected to close in the second quarter of 2021.

The MEA is the critical component of a fuel cell and accounts for about 70% of the cost of a fuel cell stack. MEAs are currently produced in Canada, Europe, Japan, Korea and China at commercial scale. Smaller scale MEA production in the United States has so far been a supply and cost bottleneck for US fuel cell vehicle production.

At full capacity, the Hyzon Innovation Center is expected to produce enough MEAs to cover the production needs for up to 12,000 hydrogen fuel cell powered trucks every year. The facility is expected to commence production of MEAs in the fourth quarter of 2021, and is planned to open with 28,000 square feet of manufacturing space, before expanding in a second phase to 80,000 square feet. Hyzon expects to eventually fill up to 50 full-time positions at this production facility.

George Gu, Chairman and Co-Founder of Hyzon, said, “The new Hyzon Innovation Center is essential to our strategy to expand the US hydrogen supply chain, reduce fuel cell costs for commercialization, and create local jobs. We chose the greater Chicago area due to its top-tier universities, national labs, equipment companies and manufacturers, and a large pool of talent for recruiting a highly-skilled workforce. We are looking forward to empowering this unique ecosystem so that we can further accelerate the energy transition and decarbonize heavy road transport.”

Craig Knight, Chief Executive Officer and Co-Founder of Hyzon, said, “We are excited about our plans to open the first high-volume MEA production line for hydrogen fuel cells in the US, which we anticipate will enable us to rapidly scale up the production of our fuel cells and deliver up to 12,000 Hyzon zero-emission heavy vehicles each year. We see a substantial uptake in Europe already, and anticipate North America will soon follow suit on this decarbonization journey for heavy transport.”

The Hyzon Innovation Center will also conduct research and development on materials for fuel cells, electrolyzers, solid-state batteries, advanced e-drive systems, autonomous driving technologies and green hydrogen production technologies.

In addition to the Hyzon Innovation Center outside Chicago, Hyzon has two facilities in Rochester, New York – one serving as a fuel cell testing facility and the other as its US headquarters, fuel cell engine production facility, and vehicle integration center. The Company currently produces commercial vehicles at its facility in Groningen, The Netherlands, through a joint venture with Holthausen Clean Technology B.V.

Senator Charles Schumer Calls on DOE to Support Green Hydrogen Production

After fighting for and securing Plug Power’s commitment to build their new ‘gigafactory’ for hydrogen fuel cell manufacturing in Rochester last month, U.S. Senator Charles E. Schumer today called on the U.S. Department of Energy (DOE) to support the newly proposed plan by New York-based Plug Power to create the first U.S.-wide network of green hydrogen production facilities. Plug Power plans on starting with the construction of a $290 million production facility at the Western New York STAMP site in Genesee county between Rochester and Buffalo. Schumer said DOE’s engagement will be a win-win in opening the door to additional federal resources to make Plug Power’s plans a reality while providing DOE with a first-ever national model for the creation of a domestic green hydrogen energy production supply chain. Schumer said with DOE support, the new 60+ job green hydrogen production facility eyed at STAMP could help lead the nation in producing carbon-free green power to run hydrogen fuel-cell-powered vehicles and equipment all while creating new green jobs.

“My message to the DOE is that with its support, New York’s own Plug Power can lead the charge in dramatically shifting the nation towards clean energy starting with the construction of its first green hydrogen production facility at the STAMP campus in Western New York,” said Senator Schumer. “The facility would create over 60 new good-paying green-energy jobs, boost the Western New York economy, and serve as a jumping-off point to create the nation’s first U.S.-wide network of green hydrogen production facilities to produce carbon-free fuel-cell power. With DOE support, this new green hydrogen fuel production facility in the heart of Western New York between Rochester and Buffalo can be a national model in efforts to achieve the Biden administration’s drastically reducing greenhouse gas emissions and creating and 10 million clean energy jobs.”

In his letter to DOE today, Schumer invited DOE officials to join him in meeting with Plug Power to discuss how DOE support, technical assistance, and resources can help supercharge Plug Power to new heights by making its plans to build its hydrogen fuel production facility in Genesee County a reality. Additionally, the senator explained that the expansion is part of Plug Power’s planned green hydrogen network to develop vertically integrated hydrogen infrastructure across the U.S. positioning the New York-based company to lead the charge in dramatically reducing the country’s greenhouse gas emissions.

Plug Power’s new production facility at STAMP would produce 40 tons-per-day of green hydrogen to supply fuel-cell-powered equipment and vehicles such as freight transportation and logistics handling equipment – some powered by fuel cells that will be manufactured at the upcoming Plug Power Gigafactory slated to open in Rochester this summer. The facility would become the first nationally recognized green hydrogen production center and the first of its kind in the Northeast United States.

Plug Power, founded in 1997 and headquartered in Latham, NY, currently employs more than 400 workers in New York to innovate, manufacture and assemble hydrogen fuel cells including about 300 workers in the Capital Region at its headquarters and Capital Region manufacturing sites in Latham and Clifton Park, and about 70 workers at its Rochester, NY manufacturing site. In 2020, Schumer successfully fought for Plug Power to build their new ‘gigafactory’ in Rochester, which will manufacture hydrogen electrolyzers, used for the production of hydrogen fuel, and hydrogen PEM fuel cells used to produce electricity to power equipment. Slated to open in the middle of next year, the ‘gigafactory’ will add another 375 employees to Plug Power’s New York workforce.

Senator Schumer’s letter to the Department of Energy appears below:

Dear Acting Secretary,

I am writing to seek the Department of Energy’s (DOE) assistance in the newly proposed plan by New York-based Plug Power to create the nation’s first U.S.-wide network of green hydrogen production facilities, starting with the construction of a $264 million production facility at the Western New York STAMP site in Genesee county between Rochester and Buffalo. With a soon-to-be nearly 975 member New York workforce and a history of reliability and strong investment in the U.S. hydrogen economy, Plug Power is perfectly positioned to meaningfully contribute towards to Biden Administration’s goals of drastically reducing greenhouse gas emissions and creating 10 million clean energy jobs.

Plug Power is striving to build five new green hydrogen fuel production facilities across the U.S., including a proposed $290 million production facility at the Western New York Science and Technology Advance Manufacturing Park (WNY STAMP) that will produce 40 tons-per-day of green hydrogen to supply the fuel-cells in advanced freight transportation vehicles and logistics handling equipment. Support and technical assistance from DOE now would create a win-win in both opening the door to additional federal resources to make Plug Power’s plans a reality while providing DOE with a first-ever national model for the creation of a domestic green hydrogen energy production supply chain. This new 60+ job green hydrogen production facility eyed at STAMP could help lead the nation in producing carbon-free green power to run hydrogen fuel-cell-powered vehicles and equipment all while creating new green jobs.

Plug Power is focused on serving the zero-emissions material handling, transportation, and industrial sectors with low-cost green hydrogen fuel that is generated using 100% renewable, zero carbon energy. This project aims to strengthen our country’s economic, environmental, and national security by utilizing domestic energy resources, including low-cost renewable energy from solar photovoltaic, wind, and hydro-electric generation facilities to produce green hydrogen. It will decrease the need for energy imports while creating industry and employment growth opportunities across a variety of markets.

Plug Power, founded in 1997 and headquartered in Latham, NY, employs over 1,217 across the world, including over 600 employees in New York with another 375 expected to be added in the coming years at the company’s new gigafactory slated to open in Rochester, NY this summer. The company is focused on building the hydrogen economy as the leading provider of comprehensive hydrogen fuel cell turnkey solutions. Plug Power created the first commercially viable market for hydrogen fuel cell technology, deploying approximately 40,000 fuel cell systems, more than any other company in the world.

I would welcome the opportunity to host DOE officials for a meeting with Plug Power to discuss how DOE can provide technical assistance, support, and resource access to this cutting-edge company to help drive the construction of this new WNY green hydrogen production facility, a strong step towards a nationwide green hydrogen supply chain.

FAURECIA ACCELERATES ITS ZERO EMISSIONS HYDROGEN STRATEGY IN CHINA

Faurecia, one of the world’s leading automotive technology companies, announced today that it has acquired a majority of CLD, one of China’s largest high-pressure tank manufacturers. The transaction will be completed once regulatory approvals are obtained in China.

Faurecia and CLD will develop and manufacture homologated type III and IV hydrogen storage tanks for the Chinese market. Headquartered in ShenYang, CLD has around 200 employees and 2 plants in Liaoning with a capacity of 30,000 tanks per year. The company is already an established and recognized player providing homologated hydrogen tanks to leading Asian commercial and light vehicle automakers.

Mathias Miedreich, Faurecia Clean Mobility EVP said. “CLD is the right partner for Faurecia to accelerate hydrogen mobility in China. By 2030, China will represent a market of at least one million fuel cell vehicles. Through our complementary technologies and industrial expertise, we will further develop CLD’s leadership.”

“We are very pleased to welcome Faurecia, one of the global leading technology companies, through its investment in CLD equity. We believe that by joining the strengths of both parties, Faurecia_CLD will become one of the major fuel cell tank manufacturers in China.” added Mrs Jiang Jiang, Chairman of CLD.

As hydrogen mobility rapidly gains momentum, the Group is now uniquely positioned to develop hydrogen storage systems and distribution services and as well as fuel cell systems (through Symbio, a joint venture with Michelin). This scope represents 75% of the full system value chain. By 2030, Faurecia forecasts the annual hydrogen vehicle production to be two and half million vehicles. Faurecia is committed to continue to invest significantly with the ambition to become a world leader in hydrogen mobility.

Biden Administration Initiates Energy Effort to Create American Jobs Including Zero Carbon Hydrogen

Today, the Biden-Harris Administration is initiating an ambitious innovation effort to create American jobs while tackling the climate crisis, which includes the launch of a new research working group, an outline of the Administration’s innovation agenda, and a new $100 million funding opportunity from the U.S. Department of Energy to support transformational low-carbon energy technologies. The announcements kickstart the Administration’s undertaking to spur the creation of new jobs, technology, and tools that empower the United States to innovate and lead the world in addressing the climate crisis.

President Biden is fulfilling his promise to accelerate R&D investments, creating a new Climate Innovation Working Group as part of the National Climate Task Force to advance his commitment to launching an Advanced Research Projects Agency-Climate (ARPA-C). The working group will help coordinate and strengthen federal government-wide efforts to foster affordable, game-changing technologies that can help America achieve the President’s goal of net zero economy-wide emissions by 2050 and can protect the American people from the impacts of droughts and flooding, bigger wildfires, and stronger hurricanes. The working group will be co-chaired by the White House Office of Domestic Climate Policy, Office of Science of Technology and Policy, and Office of Management and Budget.

“We are tapping into the imagination, talent, and grit of America’s innovators, scientists, and workers to spearhead a national effort that empowers the United States to lead the world in tackling the climate crisis,” said Gina McCarthy, President Biden’s National Climate Advisor. “At the same time, we are positioning America to create good-paying, union jobs in a just and equitable way in communities across the nation that will be at the forefront of new manufacturing for clean energy and new technology, tools, and infrastructure that will help us adapt to a changing climate.”

As the opportunity for American leadership in climate innovation is vast, the Administration is outlining key planks of an agenda the Climate Innovation Working Group will help advance:

- zero net carbon buildings at zero net cost, including carbon-neutral construction materials;

- energy storage at one-tenth the cost of today’s alternatives;

- advanced energy system management tools to plan for and operate a grid powered by zero carbon power plants;

- very low-cost zero carbon on-road vehicles and transit systems;

- new, sustainable fuels for aircraft and ships, as well as improvements in broader aircraft and ship efficiency and transportation management;

- affordable refrigeration, air conditioning, and heat pumps made without refrigerants that warm the planet;

- carbon-free heat and industrial processes that capture emissions for making steel, concrete, chemicals, and other important industrial products;

- carbon-free hydrogen at a lower cost than hydrogen made from polluting alternatives;

- innovative soil management, plant biologies, and agricultural techniques to remove carbon dioxide from the air and store it in the ground;

- direct air capture systems and retrofits to existing industrial and power plant exhausts to capture carbon dioxide and use it to make alternative products or permanently sequester it deep underground.

As a first example of the widespread innovation effort, the U.S. Department of Energy is announcing $100 million in funding via the Advanced Research Projects Agency-Energy (ARPA-E) to support transformational low-carbon energy technologies. The ARPA-E announcement invites experts across the country to submit proposals for funding to support early-stage research into potentially disruptive energy technologies, specifically encouraging inter-disciplinary approaches and collaboration across sectors.

“Today we are inviting scientists, inventors, entrepreneurs and creative thinkers across America to join us in developing the clean energy technologies we need to tackle the climate crisis and build a new more equitable clean energy economy,” said DOE Chief of Staff Tarak Shah. “The Department of Energy is committed to empowering innovators to think boldly and create the cutting-edge technologies that will usher in our clean energy future and create millions of good-paying jobs.”

In addition to supporting technologies that are near commercialization, the Climate Innovation Working Group will also emphasize research to bolster and build critical clean energy supply chains in the United States and strengthen American manufacturing. As it coordinates climate innovation across the federal government, it will focus on programs at land-grant universities, Historically Black Colleges and Universities, and other minority-serving institutions.

“Today is an important day for tackling the climate crisis through cutting-edge science, technology, and innovation. The Office of Science and Technology Policy is ready to help turbocharge climate-related innovation, and we look forward to engaging with scientists, engineers, students, and innovators all across America to build a future in which not only jobs and economic benefits but also opportunities to participate in climate innovation are shared equitably by all Americans,” said Kei Koizumi, Acting Director of the White House Office of Science and Technology Policy.