Category: Fuel Cells

-

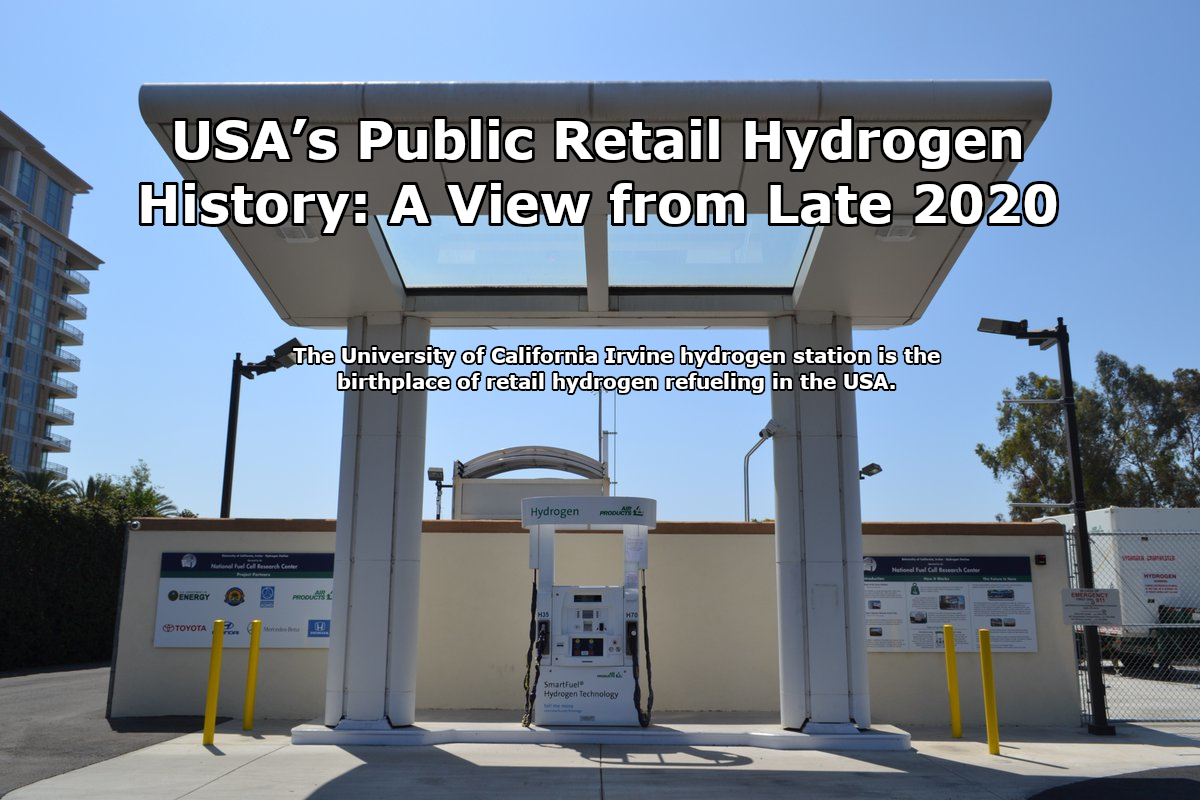

USA’s Public Retail Hydrogen History: A View from Late 2020

The new hydrogen stations opening in California are not like the ones from four years ago, they’re massive. These new stations have 1,200kgs of capacity & can be replenished in a couple of hours and keep on refueling. These new stations mark a step change in hydrogen refueling scale and represent a great time to…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2020-Q3

Each quarter, RMP reviews changes, updates, & data related to hydrogen infrastructure in the USA & Canada. Today’s publication for Q3-2020 is a real milestone in that California officially announced through GFO-19-602 the funding of over 123 new hydrogen fueling stations across the state. With approx 42 open now, the way has been paved for…

-

Zero Emission Ammonia Production from Green Hydrogen

RMP’s new post about Zero Emission Ammonia Production from Green Hydrogen examines where we are in August 2020 with regard to scaling production of green hydrogen for green ammonia. Green Ammonia pilot projects are ongoing around the world but in this post, we examine why Australia is the world leader in green ammonia & how…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2020-Q2

RMP’s USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2020-Q2 tells the story of stations outside of California. While California is the epicenter of hydrogen infrastructure in North America, this quarter’s story is about the East Coast of the USA and Canada. We have evidence of several new Air Liquide stations on the East Coast as…

-

100% Renewable Energy: Hydrogen Refueling -vs- Superchargers

It’s just past the 3 year anniversary of Elon Musk saying “All Superchargers are being converted to solar/battery power. Over time, almost all will disconnect from the electricity grid.” Since the Tesla CEO’s tweet on 6/9/2017 there are still zero off-grid 100% renewable Tesla Superchargers. Even though there are fewer hydrogen stations than BEV charging…

-

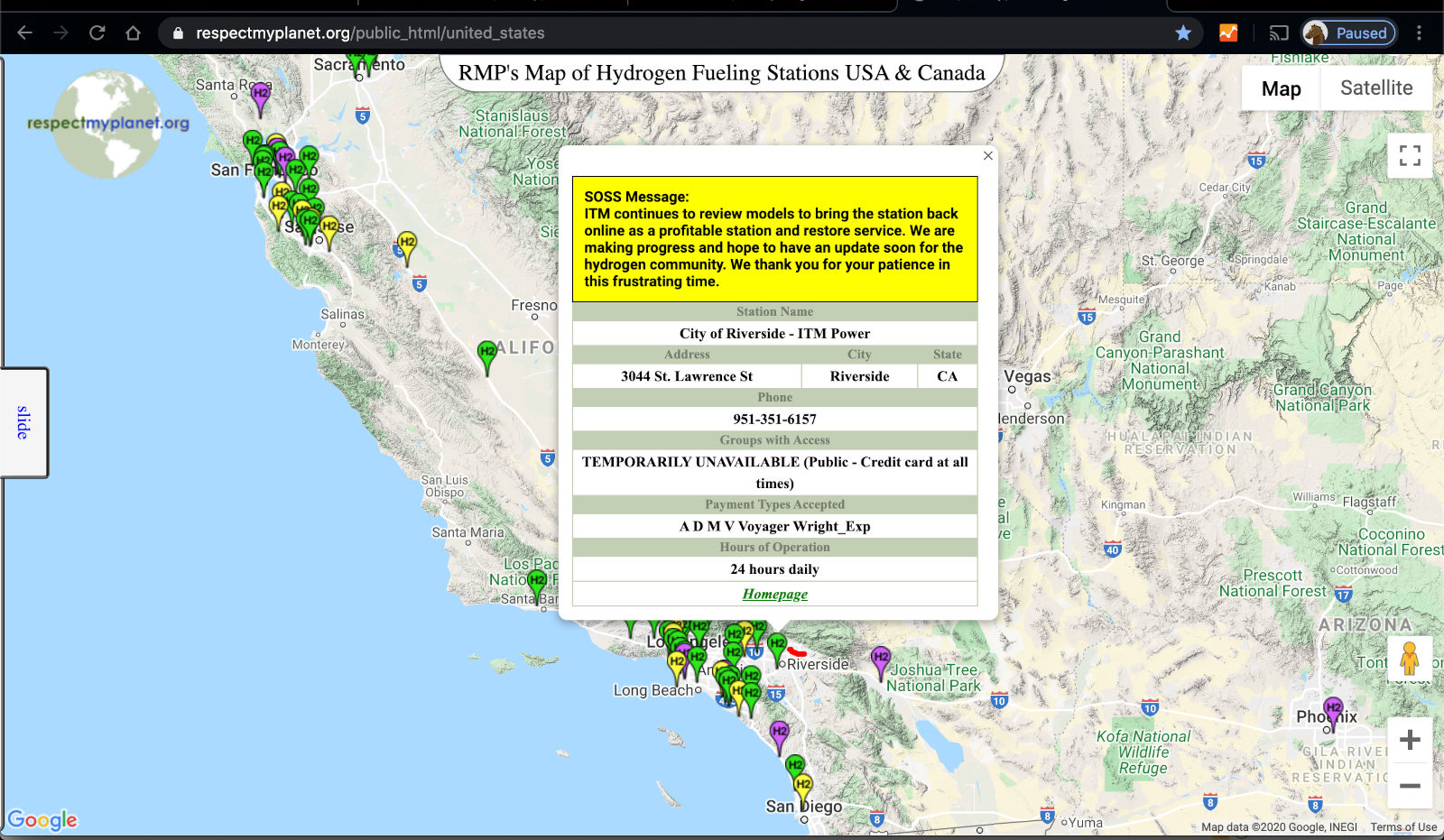

RMP’s Map of Hydrogen Stations in USA & Canada Upgraded

RMP has been updating our map of all hydrogen stations in the USA & Canada. 6 Canadian locations have been added to the map. RMP’s map is now also connected to CAFCP’s SOSS updating system. Also, this post contains bonus pics of 5 new Air Liquide stations commissioning on the East Coast of the USA.…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2020-Q1

RMPs USA & CANADA Quarterly H2 Infrastructure Report for Q1-2020 is off the press. The big story this Q is the new microgrid approval for Toyota’s Project Portal project. Also covered is the opening of the largest fast refueling h2 station in the USA at the Orange County Transit Authority located where MacArthur Blvd bisects…

-

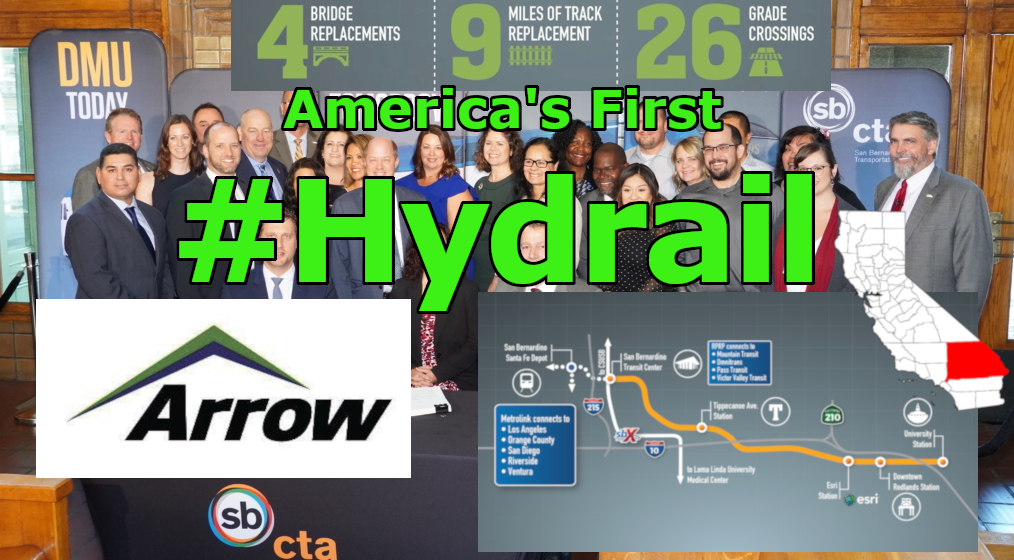

USA’s First Hydrogen Passenger Rail – San Bernadino California

The Redlands Rail Project has commenced in California and soon will host the USA’s first hydrogen powered train. Not only that, Michigan State University played an important role in helping the San Bernadino County Transportation Authority decide on using hydrogen fuel cells. Click through to learn more about the first #hydrail project in America &…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2019-Q4

Welcome new readers of RMP’s quarterly H2 infrastructure report. Each quarter RMP looks back on the major stories related to hydrogen infrastructure advancements and we compare the current AFDC database to the AFDC database in the prior quarter to see what has changed. The AFDC database is updated by the US Dept of Energy &…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2019-Q3

Each month RMP publishes an update of hydrogen infrastructure updates in the USA & Canada. RMP uses the list published by the US Dept of Energy & compares the current list with the list from last quarter. We use that data to measure what is getting added & changing each quarter and try to put…

-

USA & CANADA Quarterly H2 Infrastructure Update 2019-Q2

Read about hydrogen production & refueling infrastructure updates in the USA & Canada over the past 3 months.

-

Cleantechnica Painted Into Corner with Years of Anti-Hydrogen Bias

CleanTechnica has been biased against hydrogen so long, they’re struggling to pivot back to common sense. Zachary Shahan, CleanTechnica’s Chief Editor, has spent his career slandering hydrogen fuel cells for one reason: to support Tesla. There is only one reason CleanTechnica & its fans bash hydrogen: because Elon Musk said fuel cell cars were foolish…