Check Out Our Blog Posts:

-

GOPAL, SINGLETON BILL TO ENCOURAGE USE OF FUEL CELLS PASSES SENATE 37-0

-

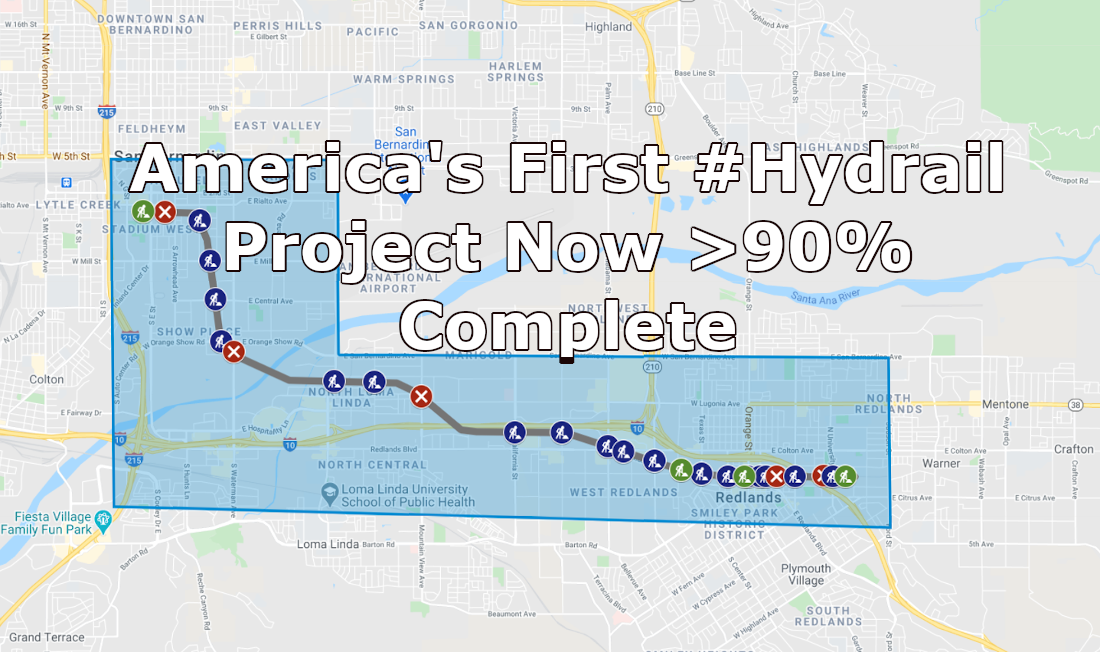

Redlands Passenger Rail Project Update – America’s 1st Hydrail >90% Complete

-

Sen. Brad Hawkins’ Bill on Hydrogen Fuel Cell Vehicles Unanimously Passes

-

GTI Preparing to Launch First-of-a-Kind Pilot with Fuel Cell Yard Trucks

-

Senator Charles Schumer Calls on DOE to Support Green Hydrogen Production

-

FAURECIA ACCELERATES ITS ZERO EMISSIONS HYDROGEN STRATEGY IN CHINA

-

Biden Administration Initiates Energy Effort to Create American Jobs Including Zero Carbon Hydrogen

-

Committee Passes Hawkins Bill Promoting Hydrogen FCEVs

-

Sunnyvale Hydrogen Station Opens

-

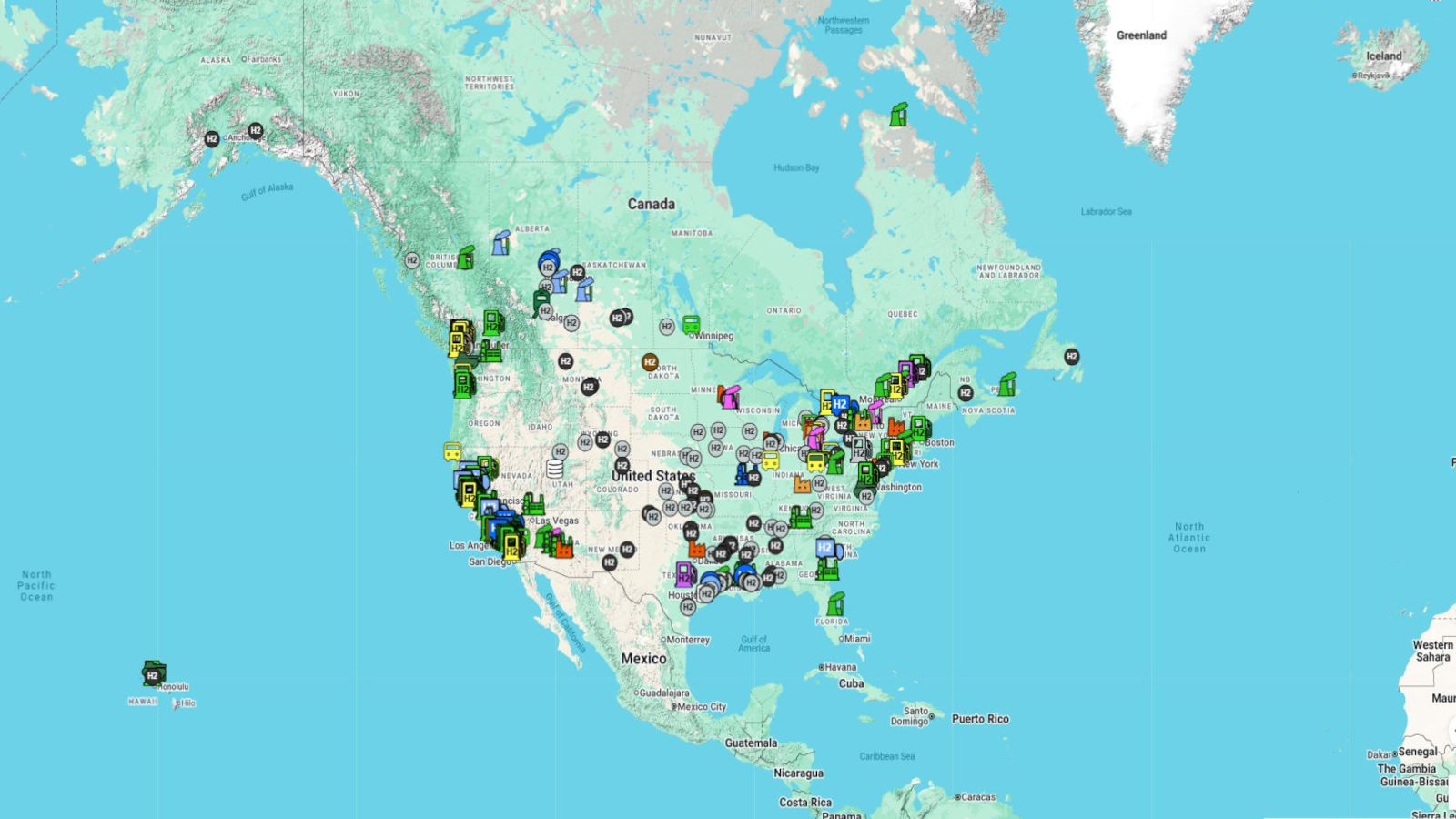

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2020-Q4

-

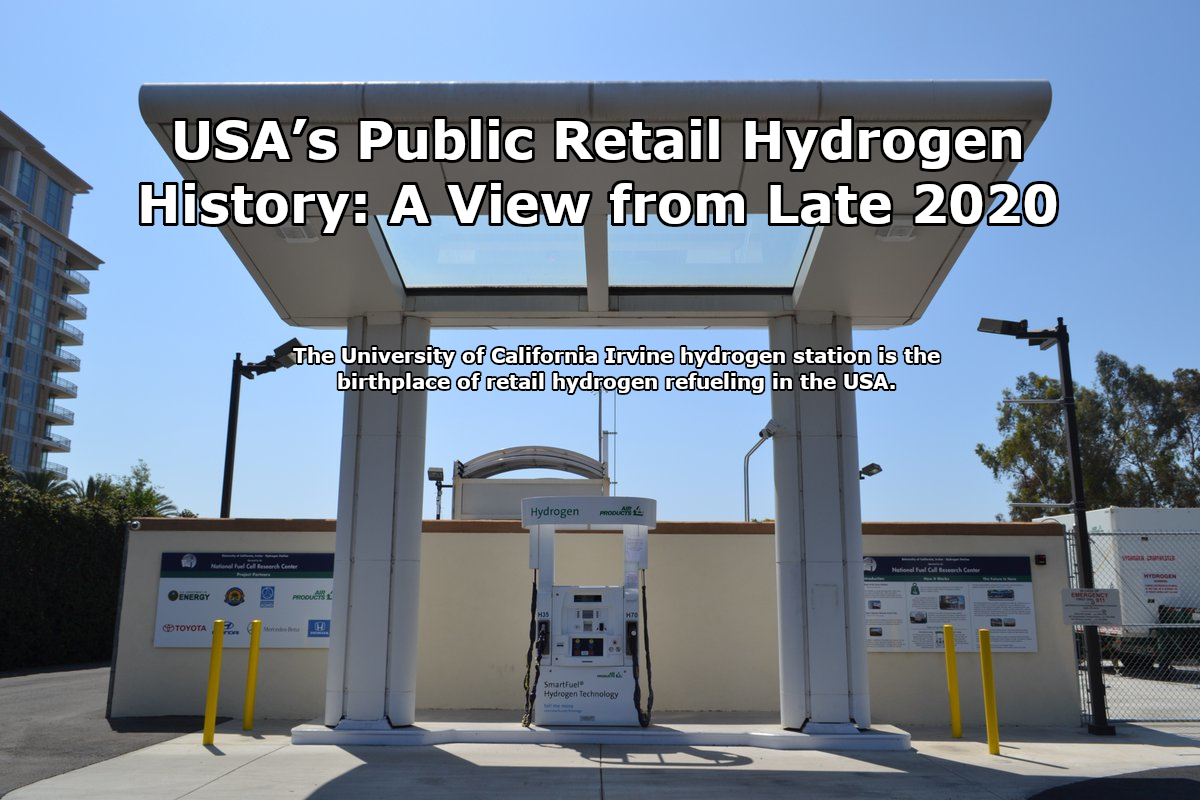

USA’s Public Retail Hydrogen History: A View from Late 2020

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2020-Q3