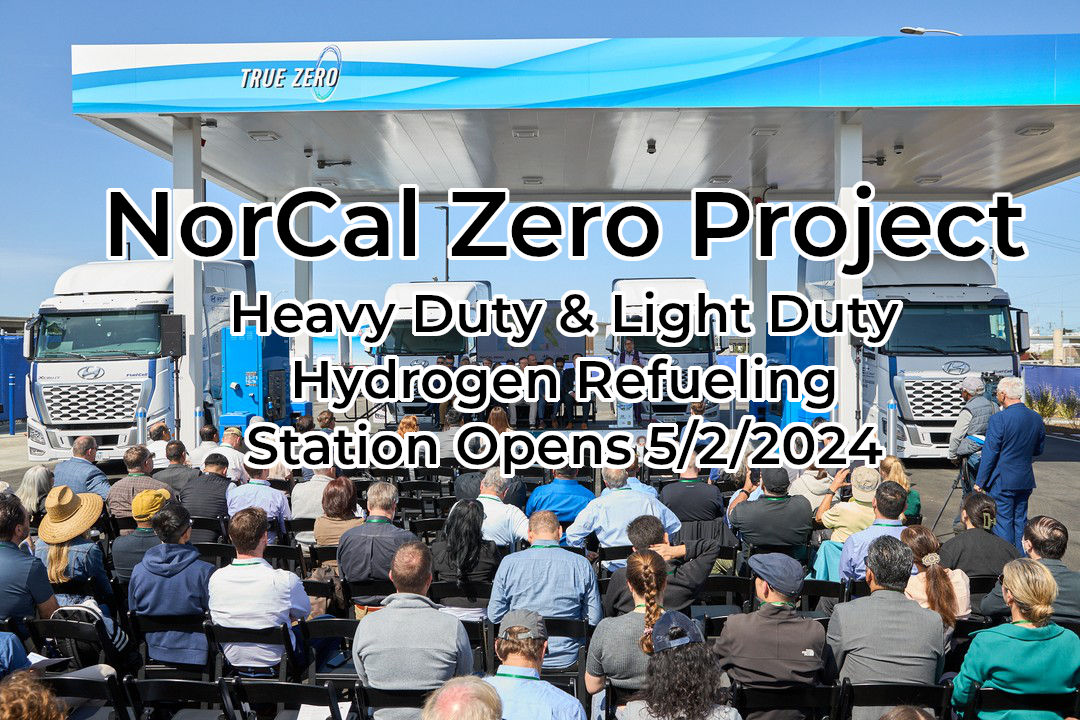

It is a milestone day for hydrogen refueling. The Center for Transportation and the Environment announces the inauguration of the NorCAL ZERO project. This new station can serve up to 200 Class 8 heavy duty trucks per day. It has a capacity of 4,000 kilograms of LH2. The station also can refuel class 1 vehicles and comes equipped with 4 light duty hoses for cars & SUVs. The $53 million collaborative effort will help deploy 30 Hyundai Xcient Class 8 hydrogen fuel cell trucks. These big rigs are the world’s first mass produced Class 8 fuel cell trucks.

West Oakland, a historically Black and Latino community, faces outsized environmental burdens from heavy industry, freeways, and diesel trucks coming to and from the Port of Oakland. CTE projects that the NorCAL ZERO project has the potential to avoid the equivalent to 2,393,124 gallons of diesel burned. Burning diesel releases NOx pollution which impacts the air people breathe and is especially burdensome near a large port like the Port of Oakland where many class 8 diesel trucks gather. Each diesel truck replaced with a zero emission hydrogen fuel cell truck will

improve public health over the six-year estimated operation of these trucks.

“Each diesel truck we replace with hydrogen helps clean the air—which has tremendous public health benefits”, said Tyson Eckerle, Senior Advisor for Clean Infrastructure & Mobility at the Governor’s Office of Business and Economic Development. “This project is a true trailblazer on so many levels, and a head start on the future we plan to build through the Alliance for Renewable Clean Hydrogen Energy Systems (ARCHES) federal hydrogen hub.”

Projects like this are even more spectacular to witness knowing that it takes such a collaborative effort to pull them off. The community stakeholders who came together include CTE, Hyundai Motor Company, Glovis America, FirstElement Fuel, Papé Group, Fielder Group, University of California Berkeley, the Port of Oakland, the City of Oakland, East Bay Municipal Utility District, and the West Oakland Environmental Indicators Project. Other official sponsors include the Alameda County Transportation Commission (Alameda CTC), Bay Area Air Quality Management District (BAAQMD), California Air Resources Board (CARB), and the California Energy Commission (CEC).

The project was financed collaboratively as well with $11.98 million from CARB’s California Climate Investments Program, $9.89 million from the CEC’s Clean Transportation Program, $3.64 million from Alameda CTC’s Clean Freight Program, $3.36 million from BAAQMD, and $24 million from project partners.

Hyundai Motor Company designed and manufactured the vehicles, which are operated by G.E.T. Freight, a truck-based freight transport business of Glovis America, hauling containers from the Port of Oakland, and cars from the Port of Richmond.

Papé Group maintains the trucks at its San Leandro facility, where technicians receive in-depth training from Hyundai on how to service the trucks. With engineering and design support from the Fiedler Group, Papé Group also upgraded its maintenance facility with hydrogen detection and ventilation equipment to safely service the trucks. Additionally, the University of California Berkeley and the West Oakland Environmental Indicators Project are assisting with data collection, community outreach efforts, and communication.

The trucks will provide Glovis with a total cost of ownership over six years that is nearly equivalent to the ownership cost of Glovis’ diesel trucks, with cost savings thereafter. The trucks, which have a range of more than 450 miles on a single fill of hydrogen, have primarily operated in drayage service, hauling freight and cars to destinations in the Bay Area and the Central Valley.

This post includes photos shared by Keith Malone courtesy of Ben Xiong at the hydrogen fuel cell partnership organization H2FCP.org. H2FCP.org provides the SOSS information that allows RMP to track the online availability of each of California’s public retail hydrogen stations. As soon as this station comes online in the SOSS system, RMP will add it to our real time hydrogen tracking page you can view here: https://www.respectmyplanet.org/public_html/california

Congratulations to all the groups and partners that help pull off this accomplishment. According to some of the plans talked about on the Hydrogen Car Owners facebook page, this new HD/LD station model marks a generational blueprint style station that can be replicated. Hydrogen’s true potential is in its scale. The famous economist Adam Smith was noted the cost of 1 pushpin is very near the cost of 10,000 pushpins given that most of the cost was in the setup of the machine. With a station like this equivalent to the machine in Smith’s example, these stations can be replicated which will drive costs down over time. Not just driving down costs of hydrogen either, driving down CO2 emissions as well. This six year project alone is estimated to eliminate over 24 metric tons of CO2 from otherwise burned diesel.

Leave a Reply