Category: Fuel Cells

-

Michael Barnard: Exposing Anti-Hydrogen Media Bias – Part 3 of 3- Critical Minerals, China’s Coal Economy, & Fair Trade

This is Part 3 of a three-part series titled: “Michael Barnard: Exposing Anti-Hydrogen Media Bias – Part 3 of 3- Critical Minerals, China’s Coal Economy, & Fair Trade” In Part 1, the topic and thesis statement for the series were presented, along with Barnard’s curriculum vitae and journalistic modus operandi. We also explored how Barnard…

-

Michael Barnard: Exposing Anti-Hydrogen Media Bias Part 2 of 3 – Heavy Ground Transportation: Rail, Bus, and Truck

This is Part 2 of a three-part series titled: “Michael Barnard: Exposing Anti-Hydrogen Media Bias – Part 2 of 3 – Heavy Ground Transportation: Rail, Bus, and Truck.” In Part 1, the topic and thesis statement for the series were presented, along with Barnard’s curriculum vitae and journalistic style. We also examined how Barnard fits…

-

Michael Barnard: Exposing Anti-Hydrogen Media Bias Part 1 of 3 – Barnard’s CV & Journalistic Style

This is Part 1 of a three-part series titled: “Michael Barnard: Exposing Anti-Hydrogen Media Bias – Part 1 of 3 – Barnard’s CV & Journalistic Style” In this section, the topic and thesis statement for the series are introduced, along with Barnard’s curriculum vitae and journalistic modus operandi. We also explore how Barnard fits into…

-

Hydrogen and Water: Putting Consumption into Perspective

Introduction Hydrogen as a clean energy source has been the subject of increasing debate, with critics often citing the water consumption required for its production. While it is true that electrolysis—the process of splitting water into hydrogen and oxygen—requires water, the broader conversation about water usage is often neglected. Many of the same people who…

-

North American Hydrogen Production Report – January 2025

Introduction Finding detailed and comprehensive hydrogen production information on the internet can be difficult. Data must be aggregated from multiple sources and estimates must be calculated based on the best data and methodologies possible. My name is Matt Wandel and I have been aggregating energy information data and hydrogen infrastructure data as a volunteer at…

-

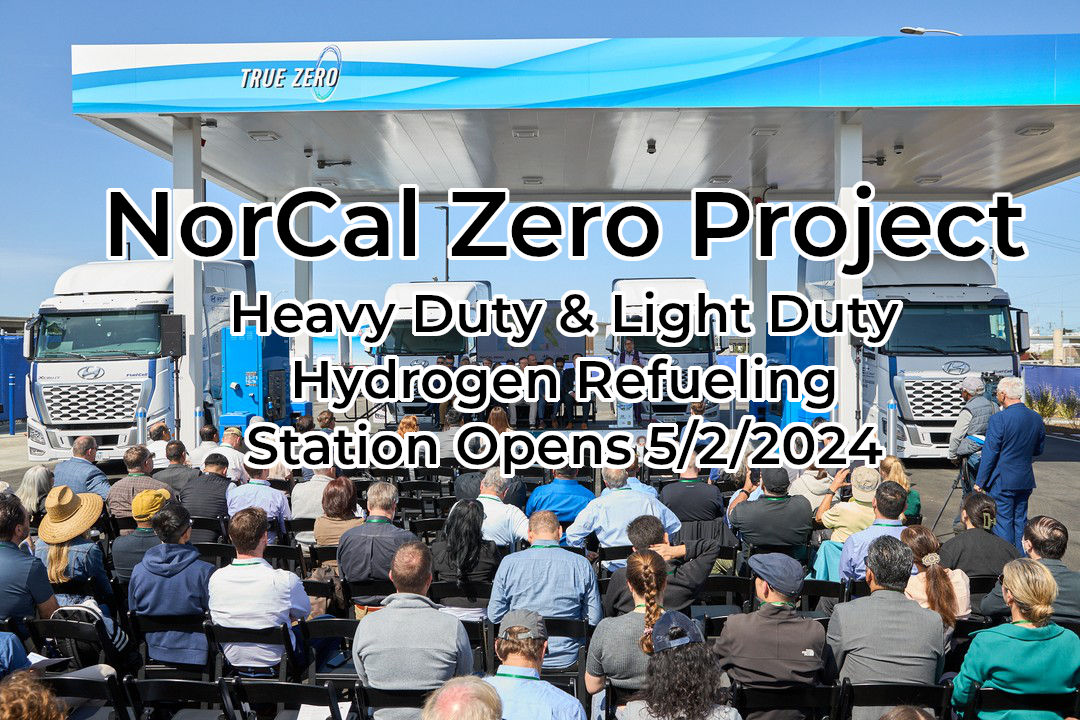

NorCal Zero Project

It is a milestone day for hydrogen refueling. The Center for Transportation and the Environment announces the inauguration of the NorCAL ZERO project. This new station can serve up to 200 Class 8 heavy duty trucks per day. It has a capacity of 4,000 kilograms of LH2. The station also can refuel class 1 vehicles and…

-

RMP’s Real Time Hydrogen Station Status Pages

RMP has upgraded our California hydrogen maps by including a new map for real time station status and a new map for stations coming soon. All stations reporting SOSS status in California are summarized on our landing page at this link and shown below (Figure 1 ). All of the pages covered in this post…

-

Michael Liebreich’s Hydrogen Ladder Debunked

Michael Liebreich is an outspoken critic of hydrogen for transportation & energy solutions. Michael purports to be an objective resource on energy information but he is a ground floor investor in ChargePoint which presents a conflict of interest to his objectivity. ChargePoint bills itself as the world’s leading EV charging network and says they focus…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2022-Q1

This quarterly report chronicles key H2 infrastructure developments & stories from the past three months and is published on the last day of the quarter. Each key news item will be highlighted with a synopsis of the key event, a link to the story, and a link to its location on RMP’s Google map of…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2021-Q4

This quarterly report chronicles key H2 infrastructure developments & stories from the past three months and is published on the last day of the quarter. Each key news item will be highlighted with a synopsis of the key event, a link to the story, and a link to its location on RMP’s Google map of…

-

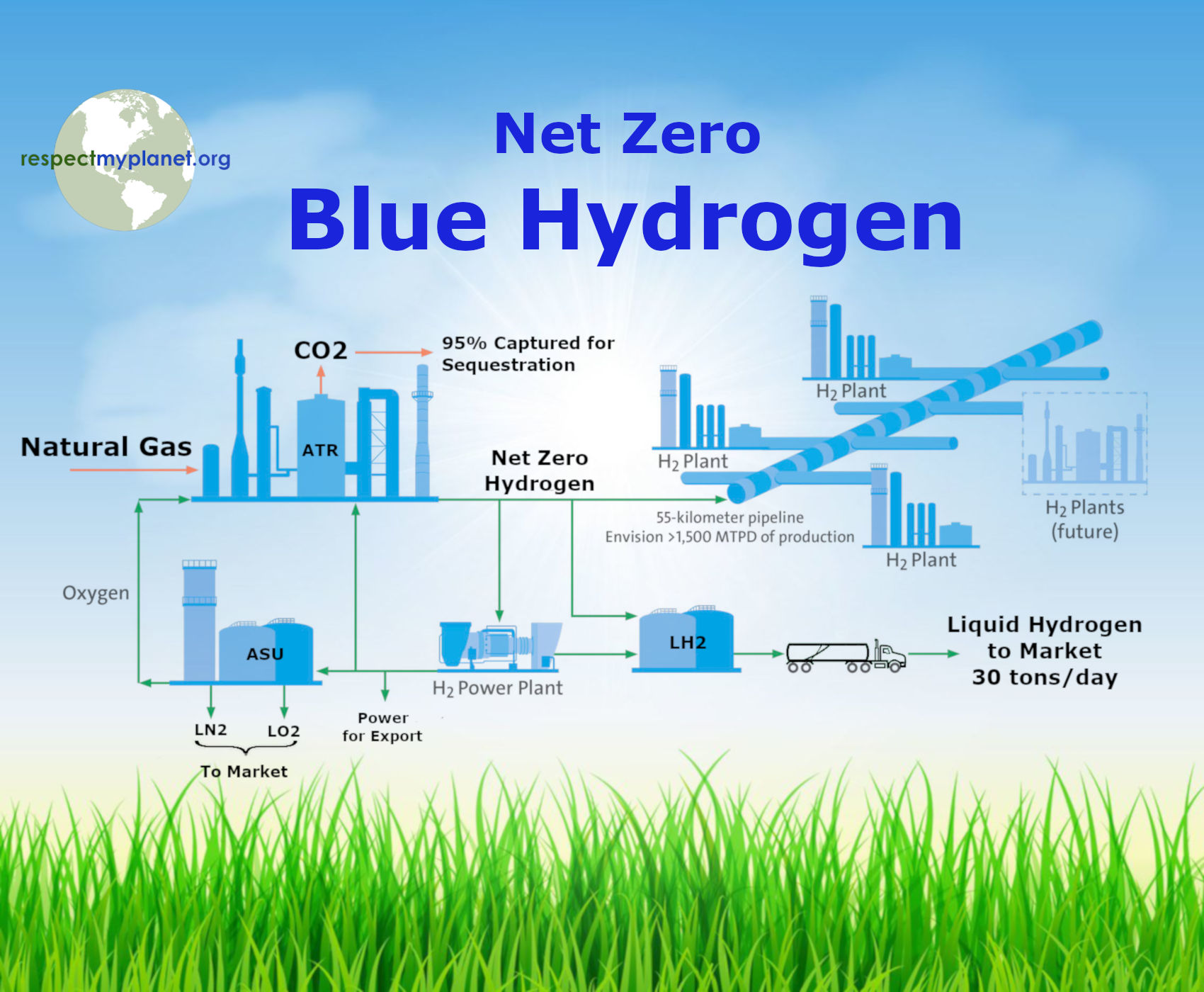

The Truth About Blue Hydrogen

Blue hydrogen is a net zero way of making hydrogen for cars, trucks, boats, ammonia, or anything for that matter. This means a lot of energy produced with no CO2, NOx, SOx, or particulate emissions. Recently some big announcements came out about blue hydrogen investments in Edmonton & Louisiana. These big announcements prompted anti-hydrogen critics…

-

USA & CANADA QUARTERLY H2 INFRASTRUCTURE UPDATE 2021-Q3

Welcome new readers of RMP’s quarterly H2 infrastructure report. Each quarter we look back on the major stories related to hydrogen infrastructure advancements and we compare the current AFDC database to the AFDC database in the prior quarter to see what has changed. The AFDC database is updated by the US Dept of Energy &…